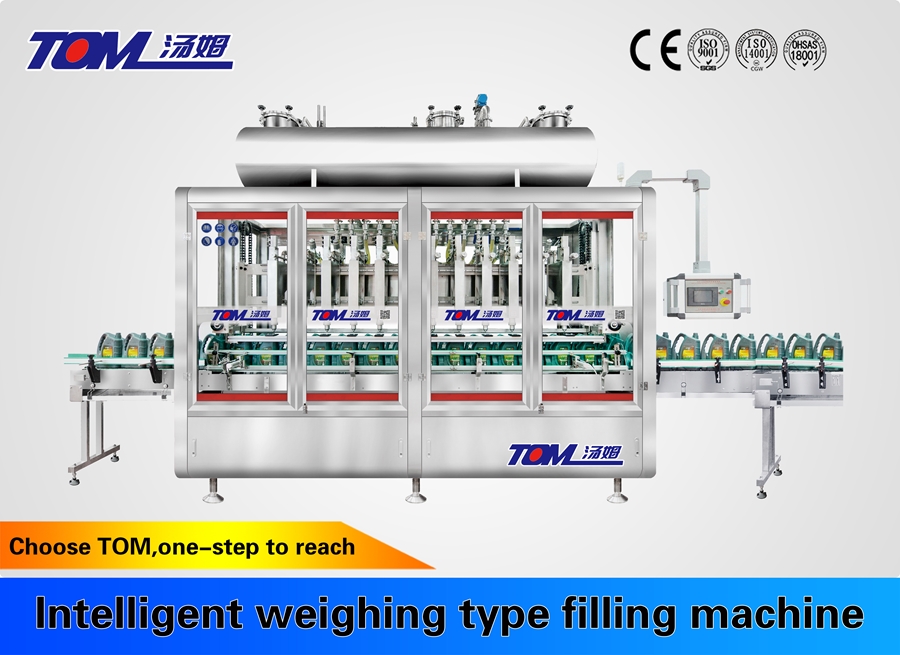

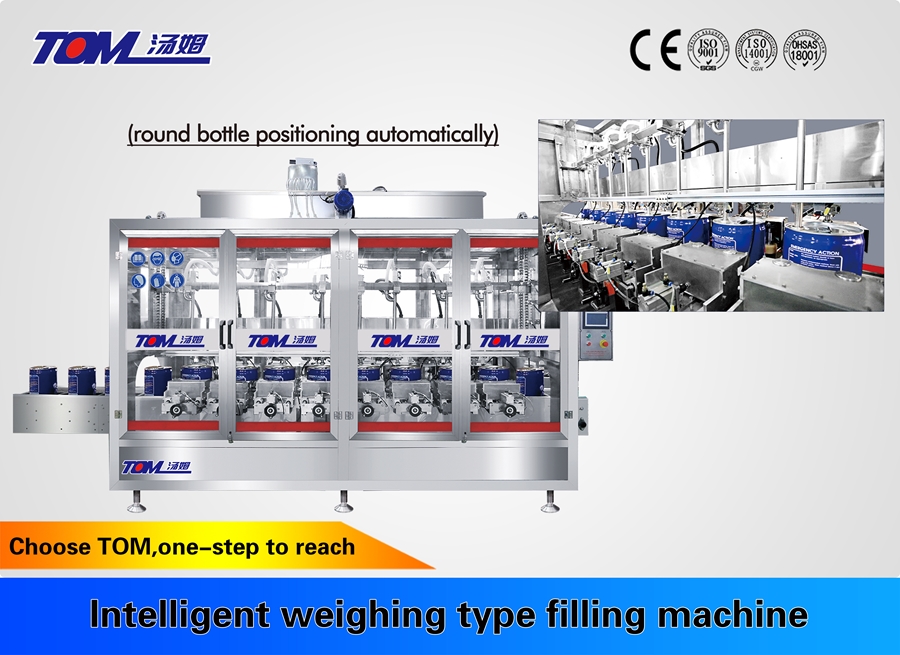

High automation linear piston filling machine (100ml-1000ml) 4/6/8/10/12/16/20 filling heads

Model: GZH-DA

Minimum order quantity: 1set

Payment term: T/T, L/C

Delivery time: single machine: 30 working days, filling line: 2 months

Delivery port: Shanghai, China

Packing: Non-fumigation wooden case inserted Iron Shelf, suitable for long time sea delivery

Certificate: ISO9001:2000, ISO14001, OHSAS18001, CE, CO

Standard: Meet GMP standard

Cleaning: with CIP cleaning system

Place of Origin: China (Mainland)

Service: Engineer is available to install and debug the equipment at customer site.

1. Filling nozzle

The filling nozzle is extended, can diving into the bottle bottom to filling, filling meanwhile going up, to prevent bubbles.

2. The position of adjustment are all carved scale or equipped with digital display, easy to adjust; and specification adjustment can be achieved without tool;

3. Part of filling hopper:

(1) The connector is all adopt fast loading clamp type, easily dismantle, clean and maintain.

(2) All pipe joints are installed a drip tight gasket, for avoiding liquid drip, ensured a long-term service life and won’t penetrate.

(3) Designing and production meet GMP. Easily dismantle, clean and maintain.

4. Energy part

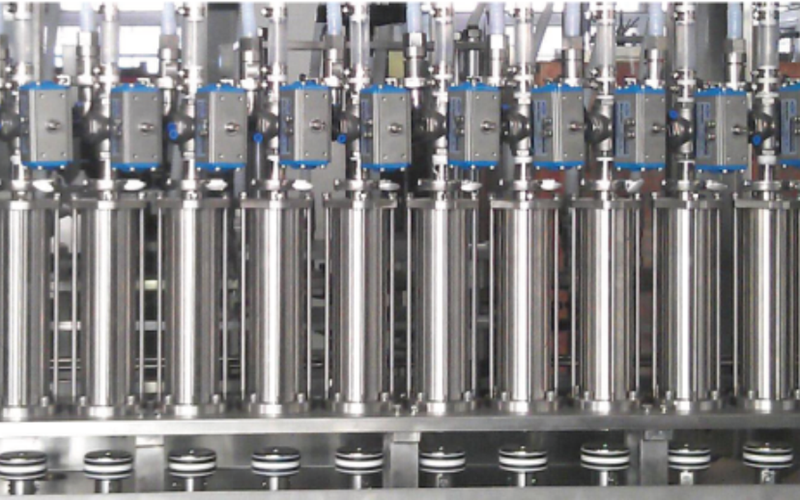

1. The energy part of this machine adopts double screw power train; ensure the piston cylinder stable working Servo system (variable speed motor + encoder) control or direct control of servo motor ensures the adjustability of measurement.

2. Double screw and double linear guide are adopted to ensure the stability of measurement.

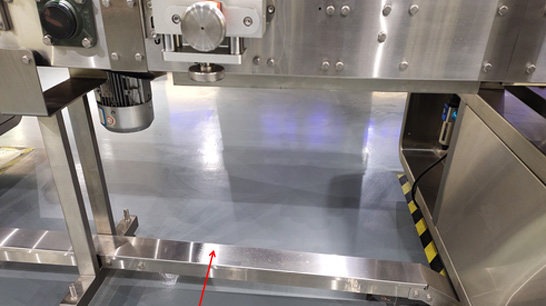

5. Piston fall off piston cylinder

For the difficulty of cleaning piston cylinder and changing sealing ring, our company designed a new filling machine which adopt fully automatic cleaning system, before clean or replace material, through man-machine interface operation, the piston can automatically fall off and return the piston cylinder, then the rest material will flow into recycling platform by gravity, save the time of manual cleaning.

6.Inlet bottle lacking detecting sensor

The machine installed bottle lack photoelectric detection and bottle blocking photoelectric detection, when the bottle lack in inlet place, machine will stop and alarm automatically; when inlet bottle enough, machine will start running automatically; when the bottle blocking in outlet place, machine will stop and alarm automatically; when bottle blocking relieve, machine will start running automatically;

7. Conveyor and drip gutter:

the conveyors before filling and after filling equipped with drip gutter also, to prevent liquid drop on ground and pollution workshop.

8.Oil-water separator:

The oil-water separator is installed before inlet main pipe, can prolong the service life of pneumatic components, main machine with air pressure protection alarm device, when the air pressure is over high or over low, main machine will stop automatically and alarm.

9.Protection door:

All doors on the machine are equipped with safety door switches and full range of interlock control. If any door is opened, the machine cannot start or stop automatically.

10.Cover lock:

All protection cover of machine is easily open and close, just press it and rotate, it is convenient for operate to make maintenance.

11. Jogging device:

The commissioning personnel can jog the equipment through the hand-held control box. The control box has the jog and emergency stop functions. The commissioning personnel can press the emergency stop button at any time even if it is debugged behind the equipment to prevent accidental injury.

12.Touch screen:

The support of touch screen adopts 360-degree rotatable bracket, which is easy to operate, simple and generous in appearance, strong in practicability, and gives the operator a kind of enjoyment at one's own will.

13.Electric box:

The electrical part are in top side of machine, can prevent water and material inside it, safety and environmental.

14.Cable trays:

simple structure, beautiful appearance, flexible configuration and convenient maintenance, so that the cables and air pipes on the site are not messy.