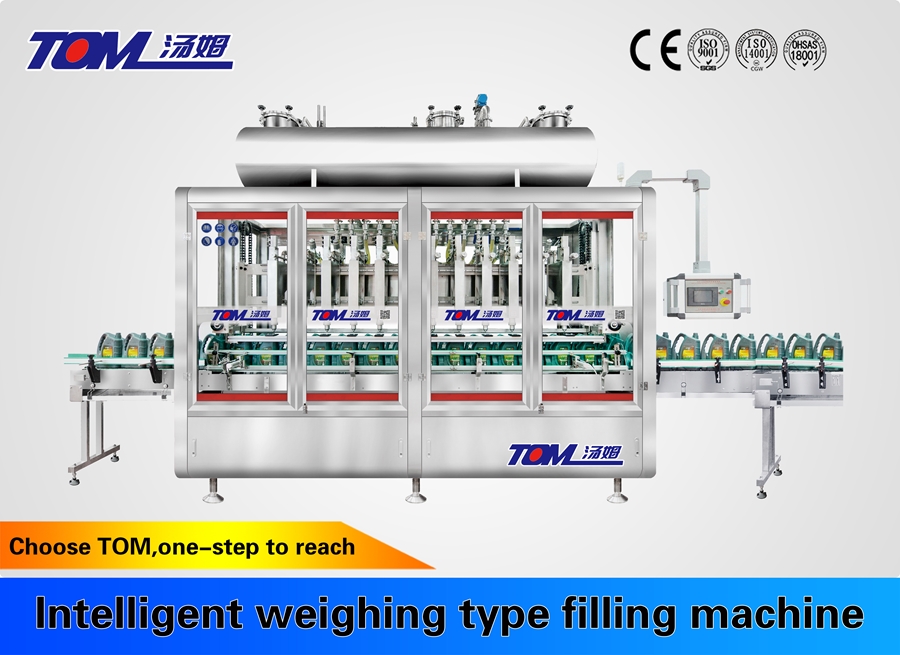

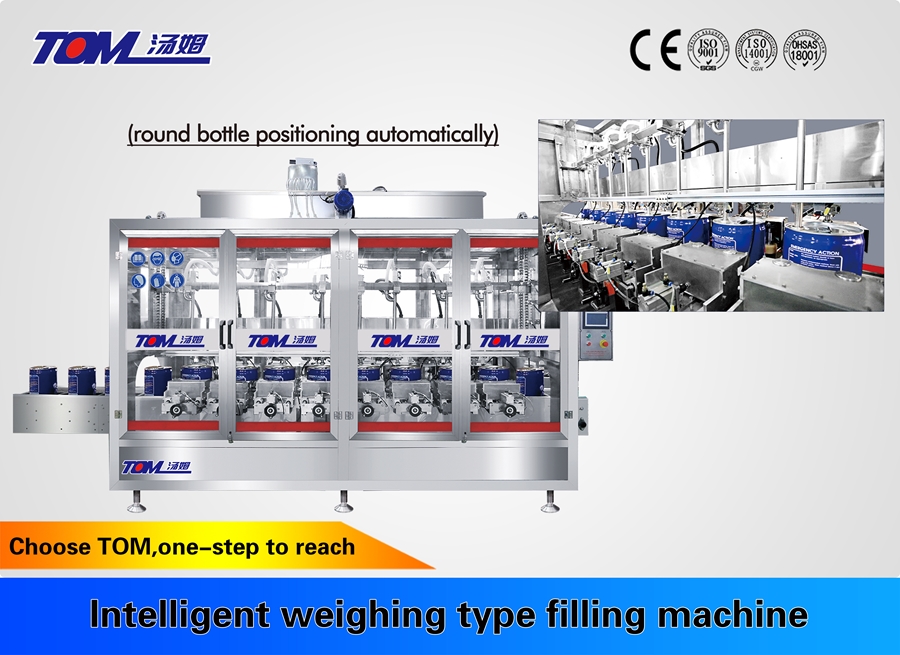

Automatic Linear Barrel weighing filling machine

Model: GZC-TA1 Series

Minimum order quantity: 1set

Payment term: T/T, L/C

Delivery time: 45 working days

Delivery port: Shanghai, China

Packing: Non-fumigation wooden case inserted Iron Shelf, suitable for long time sea delivery

Certificate: ISO9001:2000, ISO14001, OHSAS18001, CE, CO

Standard: Meet GMP standard

Cleaning: easy cleaning

Place of Origin: China (Mainland)

Service: Engineer is available to install and debug the equipment at customer site.

1. Filling part:

Automatic dive filling when filling, automatically rise after filling to prevent material splashing. There is a liquid dripping tray under the filling nozzle to prevent material leakage. The filling head has a rough and fine filling function to ensure the filling speed and accuracy.

2. The feeding pipe is made of stainless steel high-temperature hose, and the joint is fastened with a quick connector to ensure easy removal. Filling nozzle zero-leakage, no splash oil

3. The filling head can generally be lifted up and down, fixed in the horizontal direction, and correspond to the scales below. Different barrels are transported to the center of the scale by the transport positioning device (to adapt to different types of barrel filling).

4.Inlet bottle lacking detecting sensor

The machine installed bottle lack photoelectric detection and bottle blocking photoelectric detection, when the bottle lack in inlet place, machine will stop and alarm automatically; when inlet bottle enough, machine will start running automatically; when the bottle blocking in outlet place, machine will stop and alarm automatically; when bottle blocking relieve, machine will start running automatically;

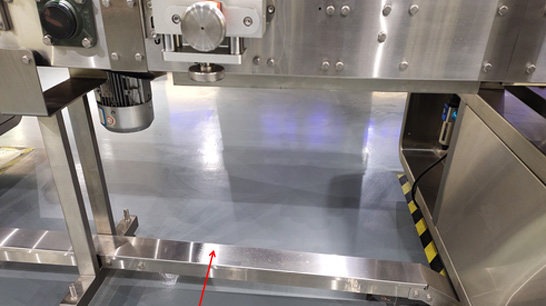

5. Conveyor and drip gutter:

the conveyors before filling and after filling equipped with drip gutter also, to prevent liquid drop on ground and pollution workshop.

6.Oil-water separator:

The oil-water separator is installed before inlet main pipe, can prolong the service life of pneumatic components, main machine with air pressure protection alarm device, when the air pressure is over high or over low, main machine will stop automatically and alarm.

7.Protection door:

All doors on the machine are equipped with safety door switches and full range of interlock control. If any door is opened, the machine cannot start or stop automatically.

8.Cover lock:

All protection cover of machine is easily open and close, just press it and rotate, it is convenient for operate to make maintenance.

9. Jogging device:

The commissioning personnel can jog the equipment through the hand-held control box. The control box has the jog and emergency stop functions. The commissioning personnel can press the emergency stop button at any time even if it is debugged behind the equipment to prevent accidental injury.

10.Touch screen:

The support of touch screen adopts 360-degree rotatable bracket, which is easy to operate, simple and generous in appearance, strong in practicability, and gives the operator a kind of enjoyment at one's own will.

11.Electric box:

The electrical part are in top side of machine, can prevent water and material inside it, safety and environmental.

12.Cable trays:

simple structure, beautiful appearance, flexible configuration and convenient maintenance, so that the cables and air pipes on the site are not messy.