Intelligentfollowing type capping machine 1/2 capping heads

Model: FGX-1/2A

Minimum order quantity: 1set

Payment term: T/T, L/C

Delivery time: 45 working days

Delivery port: Shanghai, China

Packing: Non-fumigation wooden case inserted Iron Shelf, suitable for long time sea delivery

Certificate: ISO9001:2000, ISO14001, OHSAS18001, CE, CO

Standard: Meet GMP standard

Cleaning: easy cleaning

Place of Origin: China (Mainland)

Service: Engineer is available to install and debug the equipment at customer site.

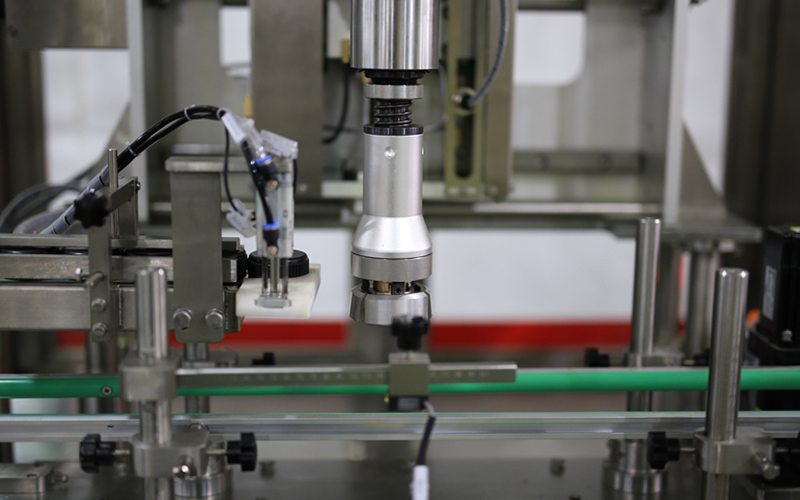

1. High-precision screw cap, precise grip, reliable screw cap, stainless steel, professional surface treatment, three claws in a triangular shape, internal wear-resistant tendon strip to prevent metal from directly contacting the lid , reduce the wear of the cap.

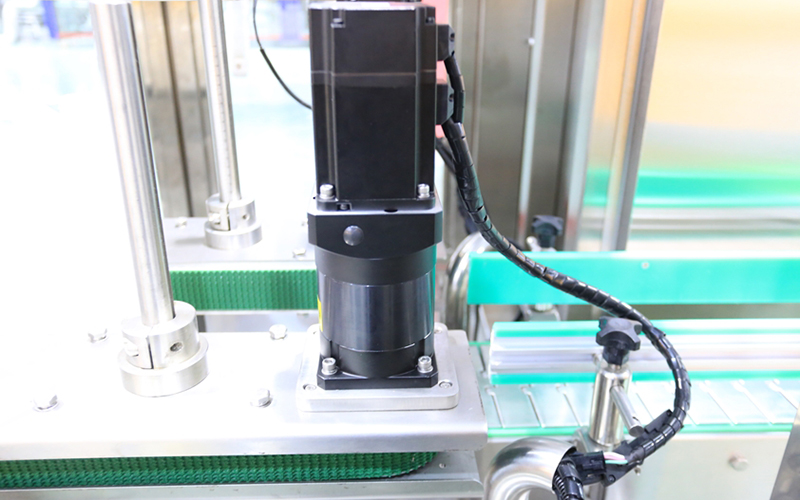

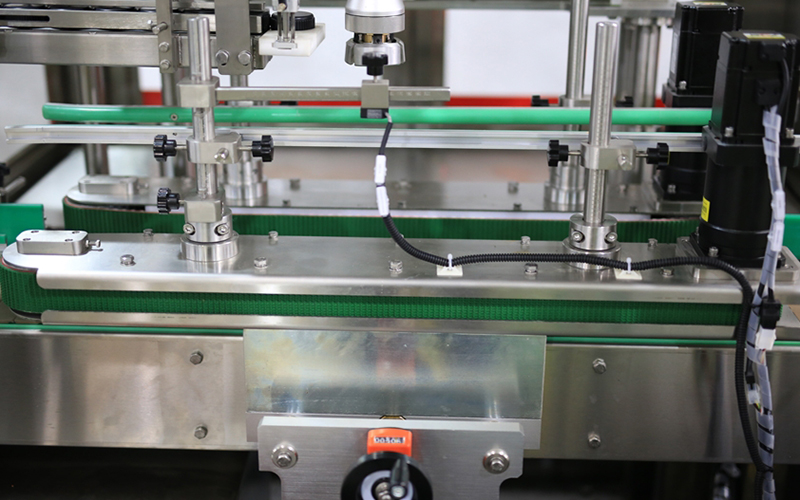

2. The bottle is clamped firmly by belt during the capping process, and at the same time, it plays the Z-axis direction. The servo motor controls the bottle clamping speed and keeps pace with the capping motor, so that the gripper can precisely match the bottle mouth.

3. Adopting the imported motion module controller + motion module control follow-up capping method, the clutch is stable and the positioning accuracy is high.

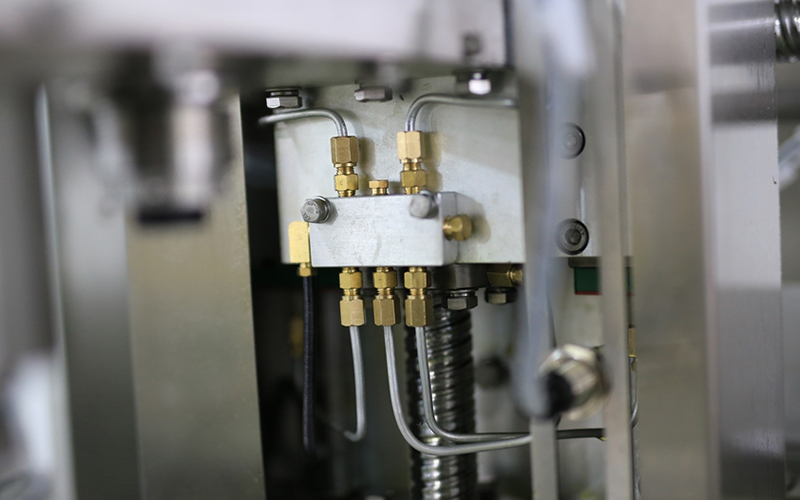

4. The equipment is equipped with oil pressure distributor and automatic oil pipeline to ensure the lubrication effect of moving parts of the equipment and improve the life cycle of the equipment.

5. The capping device adopts the principle of centrifugal movement to make the cap inside enter the track and perform the front and back cap treatment. The photoelectric detect and the compressed air blow, makes the back cap return into the cap sorter bowl, and the positive cap enters the cap chute, cap sorting speed can be adjusted by frequency conversion.

6. The main machine lifting controlled by transducer, controlled the capping machine’s height adjusted, to suitable different bottles’ height.

7. The capping head is driven by the cylinder, and the torque and force control system is used to ensure the capping effect and the injury cap. The servo motor drives the screw cap and lift, the positioning is accurate, the operation is smooth, safe and efficient.

8.Inlet bottle lacking detecting sensor

The machine installed bottle lack photoelectric detection and bottle blocking photoelectric detection, when the bottle lack in inlet place, machine will stop and alarm automatically; when inlet bottle enough, machine will start running automatically; when the bottle blocking in outlet place, machine will stop and alarm automatically; when bottle blocking relieve, machine will start running automatically;

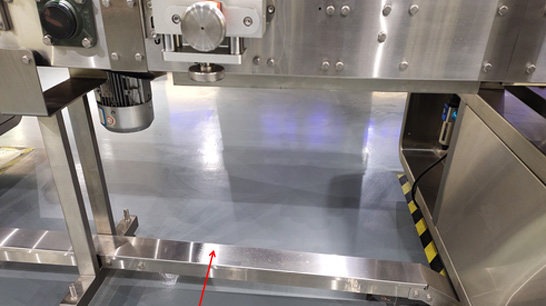

9. Conveyor and drip gutter:

the conveyors before filling and after filling equipped with drip gutter also, to prevent liquid drop on ground and pollution workshop.

10.Oil-water separator:

The oil-water separator is installed before inlet main pipe, can prolong the service life of pneumatic components, main machine with air pressure protection alarm device, when the air pressure is over high or over low, main machine will stop automatically and alarm.

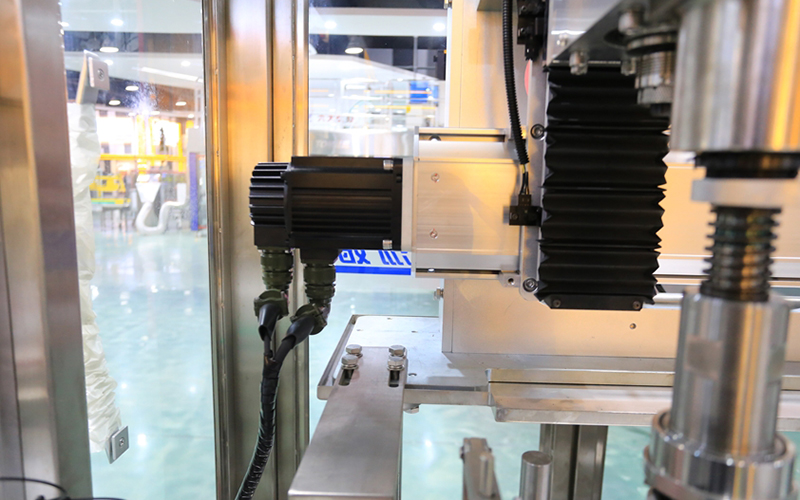

11.Protection door:

All doors on the machine are equipped with safety door switches and full range of interlock control. If any door is opened, the machine cannot start or stop automatically.

12.Cover lock:

All protection cover of machine is easily open and close, just press it and rotate, it is convenient for operate to make maintenance.

13. Jogging device:

The commissioning personnel can jog the equipment through the hand-held control box. The control box has the jog and emergency stop functions. The commissioning personnel can press the emergency stop button at any time even if it is debugged behind the equipment to prevent accidental injury.

14.Touch screen:

The support of touch screen adopts 360-degree rotatable bracket, which is easy to operate, simple and generous in appearance, strong in practicability, and gives the operator a kind of enjoyment at one's own will.

15.Electric box:

The electrical part are in top side of machine, can prevent water and material inside it, safety and environmental.

16.Cable trays:

simple structure, beautiful appearance, flexible configuration and convenient maintenance, so that the cables and air pipes on the site are not messy.